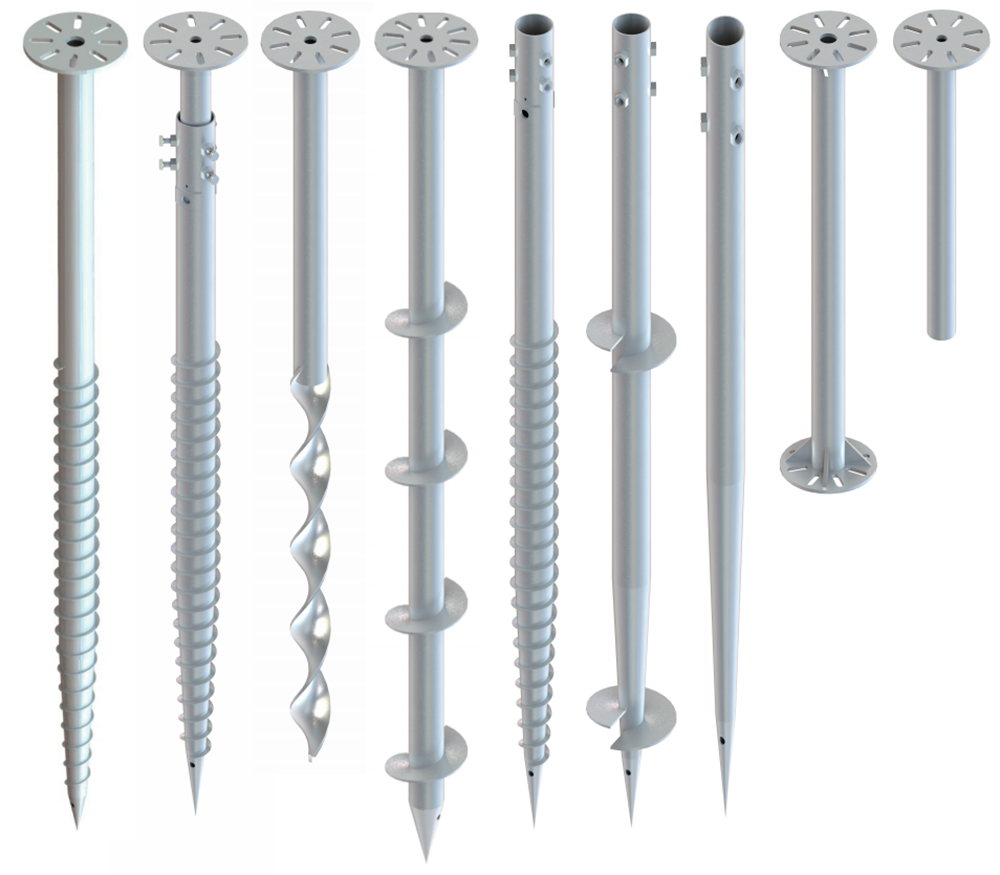

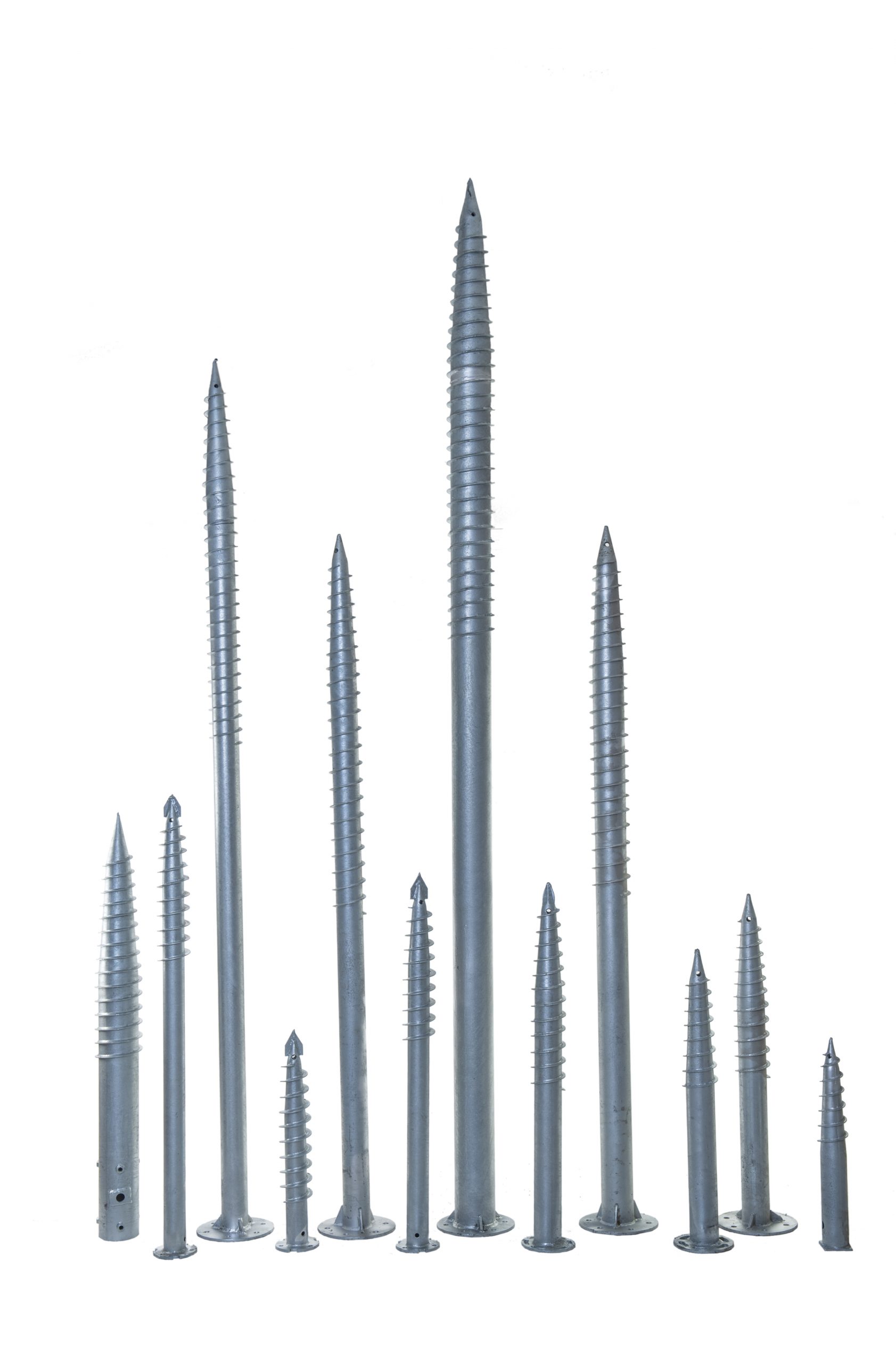

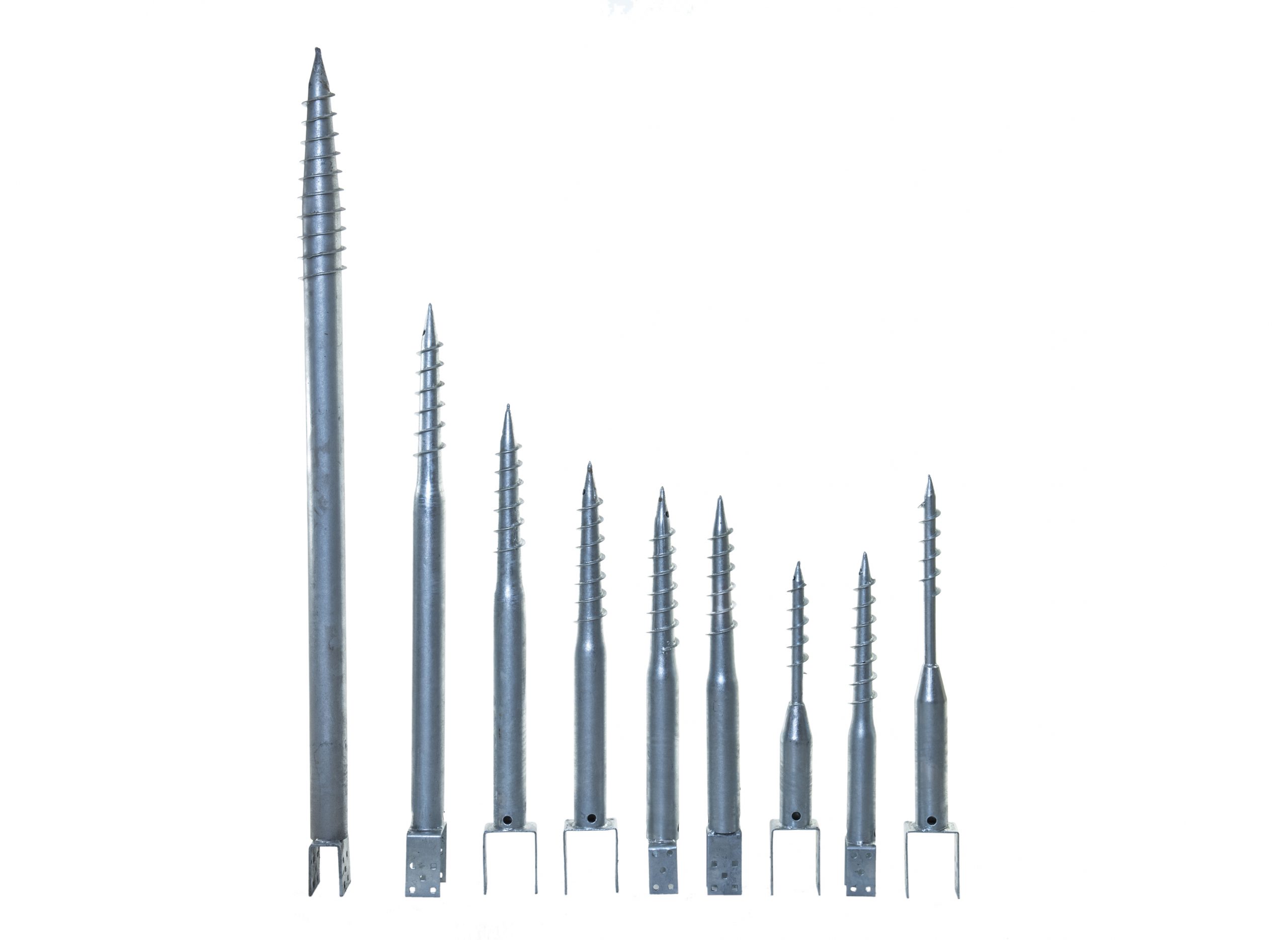

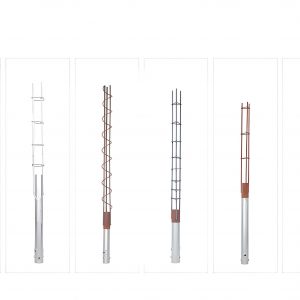

Hot Dip Galvanized Steel Spiral Helical Ground Screw Pile (HDG)

Material: Spiral ground piles made of high-quality steel have high strength and strong corrosion

resistance, ensuring long-term durability. Using hot-dip galvanized steel can enhance its corrosion

resistance and extend its service life.

Design structure: Reasonable blade size, pitch, and pile diameter are crucial. The leaves are wide

and have a moderate pitch, which can increase the contact area and friction with the soil, and

enhance the ability to resist pulling and overturning. The diameter of the pile body is thicker and

has better compressive strength.

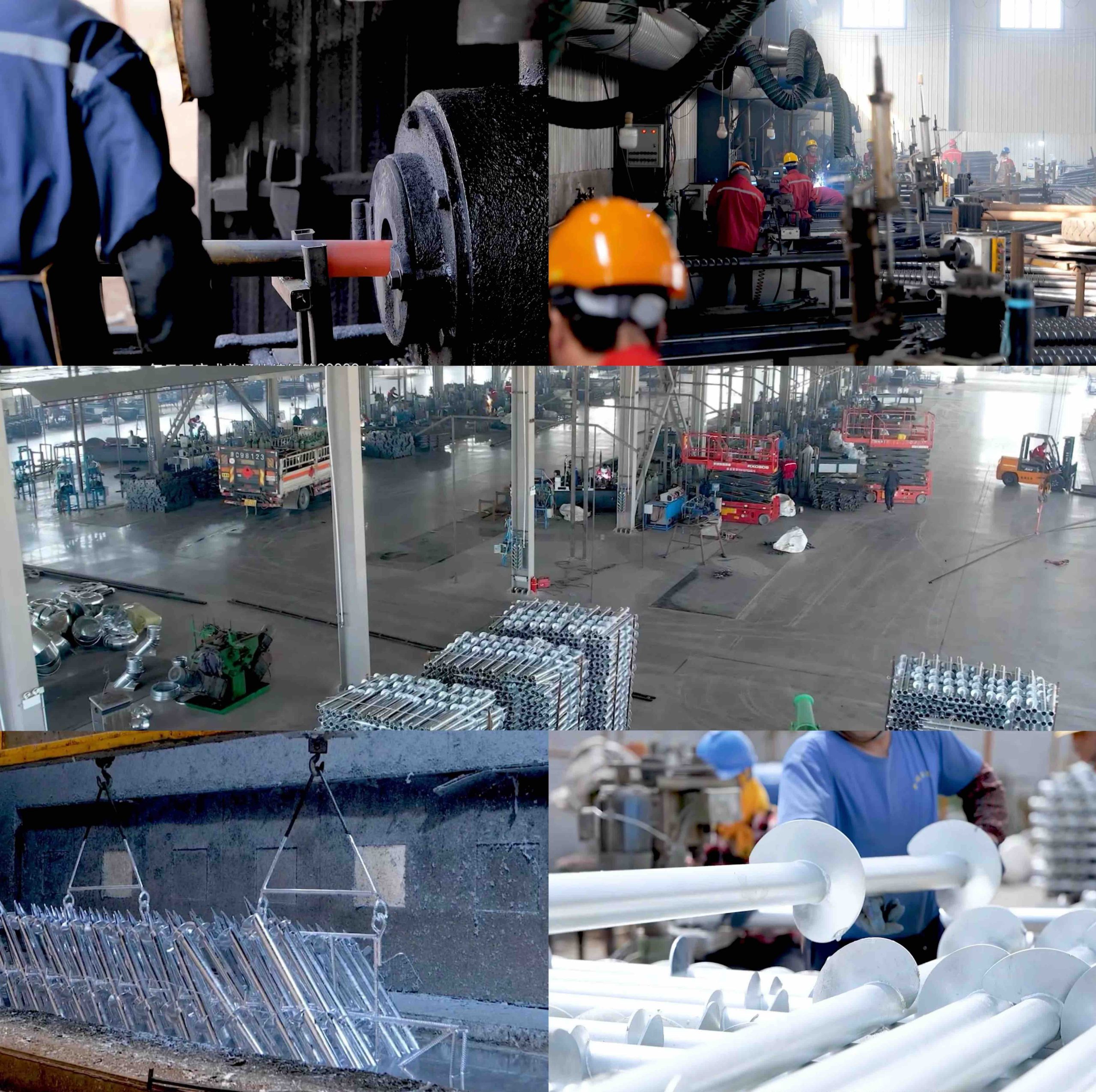

Factory-Direct Precision, Global Expertise

As an integrated manufacturer-exporter, we control every process from raw material sourcing to

final assembly. Our in-house R&D team and ISO 9001-certified factories ensure consistent quality

with 0% middleman markup.

Engineered at Our Foundry, Perfected for Your Project

Unlike trading companies, we custom-engineer products in our 50,000㎡ production facility.

Real-time production tracking and on-site quality inspections guarantee 48-hour defect resolution.

OEM/ODM Vertical Integration

Owning the complete supply chain – from steel rolling mills to coating lines – allows 15% cost

savings and 10-day lead time advantages. Production can be based on customer drawings or

customer demand self-research and development production.

Quality First Customer First

Our mission is to providing exceptional products and services to our customers. We aim to make a

positive impact on our customers, employees, partners, and the wider community. Sincerely Hope

to cooperate with the customer both in China and abroad based on equality and mutual benefit.

Contact email: sales01@tjhuafong.com Phone/Whatsapp/Wechat: +8613602065610.